The city is currently attracting investment into 14 green industrial parks covering over 3,800 hectares, with the aim to draw high-quality capital inflow.

Moving towards Net Zero

According to the Management Board of Export Processing Zones and Industrial Parks of Ho Chi Minh City, from now until 2033, in addition to the 17 existing zones, the city plans to expand and invest in 14 new industrial parks with a total area of 3,833 hectares. The city will pilot the transformation of five zones into models of high-tech parks, eco-industrial parks, urban-industrial-service complexes, and logistics centres. These include Tan Thuan Export Processing Zone and the Hiệp Phước, Tan Binh, Cat Lai, and Binh Chieu industrial parks.

According to Giang Ngoc Phuong, Deputy General Director of Hiep Phuoc Industrial Park Joint Stock Company (Nha Be District), many enterprises in the park have gradually embraced the circular economy and “industrial symbiosis” models in efforts to realise the eco-industrial park concept and aim for a Net Zero goal. For instance, at the Hiep Phuoc cement grinding station of Siam City Cement (Vietnam) Co., Ltd. (INSEE), the portfolio of “green” cement products features low-carbon emissions thanks to increased use of fly ash and steel slag by-products, helping to reduce the clinker ratio in cement.

In addition, the co-processing of waste in INSEE’s cement kilns allows for the thorough destruction of non-recyclable waste at high temperatures while also utilising heat from waste through a waste heat recovery system to replace part of the fossil fuel input. This significantly reduces CO₂ emissions and relieves pressure on landfills.

Dao Nguyen Khanh, Head of Sustainable Development at INSEE, stated that all INSEE’s plants have achieved low CO₂ emissions, with an emission level of 374kg per tonne of cement in 2024 — 44% lower than the industry average. This is a mandatory global criterion of the company to ensure cleaner production and reduced environmental emissions, aiming towards Net Zero as committed by the Government of Viet Nam.

Thanks to this model, 40 enterprises in Hiep Phuoc Industrial Park have saved approximately 43.3 billion VND per year by reducing electricity consumption by 6,854 MWh; reducing water consumption by more than 151,000 m³; and cutting greenhouse gas emissions by nearly 6,000 tonnes of CO₂ annually.

Regarding high value-added transformation models, Nguyen Tan Phong, Deputy General Director of Tan Thuan Co., Ltd. (the developer of Tan Thuan Export Processing Zone in District 7), stated that with the strategic goal of becoming a modern industrialised country that embraces technological innovation and digital transformation, Tan Thuan Export Processing Zone is moving towards Industry 4.0 and cooperating with city authorities to take the lead in digital transformation and innovation. The company aims to attract and organise high-quality human resource training services by partnering with institutes and universities, transitioning towards a model with less manual labour and more “intellectual value”.

Deep transformation of industrial parks

Le Van Thinh, Head of the Management Board of Export Processing Zones and Industrial Parks of Ho Chi Minh City, stated that in the new development phase, for existing industrial parks, the city plans to retain all industrial land while implementing deep transformation to improve operational quality and efficiency. It will restructure industrial sectors towards high-tech development, smart and ecological industrial parks, and urban-industrial-service zones. The city also prioritises regional connectivity with Binh Duong and Ba Ria–Vung Tau to form industrial linkages and attract efficient investment.

The city’s orientation for new industrial parks is to follow smart, modern, and specialised models, aiming to establish intra and inter-park industrial clusters. The Management Board commits to providing the best possible conditions for investors joining new export processing zones, ensuring streamlined administrative procedures and digital transformation, while implementing incentive policies and investment support as well as completing necessary procedures and conditions to establish new industrial parks.

According to the planning released by the Management Board, Ho Chi Minh City has laid out the spatial arrangement and distribution of its industrial regions as follows:

Region 1 (Binh Chanh District): A concentrated industrial area focusing on key sectors.

Region 2 (Cu Chi and Hoc Mon Districts): A supporting industrial area linked with regional connections.

Region 3 (Thu Duc City): An innovation and high-tech region for developing potential industries.

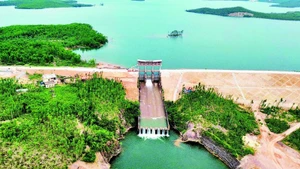

Region 4 (Nha Be and Can Gio Districts): A clean industrial area associated with the marine economy, environmental protection, and nature conservation.

Giang Ngoc Phuong believes that the eco-industrial park model is an essential requirement to meet both legal regulations and market demands. Currently, Vietnamese goods must not only satisfy domestic demand but also meet export requirements, especially for markets in developed countries. There is an increasing trend for goods to be environmentally friendly, with low fuel consumption and reduced emissions.

Dao Xuan Duc, Chairman of the Ho Chi Minh City Industrial Park Business Association, stated that to accelerate the transformation of operational models, enterprises need supportive policies from the state on credit, investment, and technological innovation. At the same time, the city must synchronise transport and logistics infrastructure investment and orient the attraction of priority sectors to effectively call for and attract investors.

As a key growth engine of the Southeast region, influencing and spreading development to neighbouring localities, Ho Chi Minh City is shifting its industrial parks towards eco-industrial models with higher intellectual content and a focus on high-quality human resources. This will enhance competitiveness and meet global trends in green and sustainable development.